Contents

- What Are Haskel Pumps?

- Overview of Haskel Technology

- Key Features of Haskel Pumps

- Why Choose Haskel Pumps?

- Applications of Haskel Pumps in High-Pressure Environments

- Oil and Gas Industry

- Hydrogen Energy Systems

- Industrial Manufacturing

- Aerospace and Defense

- Research and Development

- How Haskel Pumps Enhance Industrial Operations

- Improving System Efficiency

- Enhancing Safety Standards

- Reducing Costs Over Time

- Comparative Analysis: How Haskel Pumps Outperform Competitors in High-Pressure Environments

- Superior Engineering

- Versatility Across Applications

- Reliability Under Extreme Conditions

- Cost-Effectiveness Over Time

- Advanced Safety Features

- Innovative Technology Integration

- Innovations in Haskel Pump Technology

- Advancements in Hydraulically Driven Gas Compressors

- Integration with High-Pressure Systems

- Smart Pump Technology

- Case Studies: Real-World Applications of Haskel Pumps

- Oil and Gas Exploration

- Aerospace Testing

- Environmental Impact of Haskel Pumps

- Energy Efficiency

- Reduction in Waste

- Support for Renewable Energy

- Maintenance Best Practices for Haskel Pumps

- Regular Inspections

- Use Genuine Parts

- Training and Expertise

- Maintenance Schedules

- Conclusion

Haskel pumps have established themselves as leaders in the high-pressure equipment industry. Renowned for their exceptional performance and unwavering reliability, these pumps serve critical roles across various sectors, including oil and gas, hydrogen energy, and industrial manufacturing.

Their ability of a haskel pump to operate efficiently in high-pressure environments makes them a preferred choice for engineers, technicians, and procurement managers seeking reliable equipment solutions.

What Are Haskel Pumps?

Overview of Haskel Technology

Haskel pumps are pneumatic-driven liquid pumps designed to convert compressed air into hydraulic power. This design allows them to generate pressures exceeding 100,000 psi (7000 bar), far surpassing conventional hydraulic pumps.

The internal area ratio of the pump is crucial, as it determines the maximum output pressure achievable. Haskel’s technology is characterised by simplicity and efficiency; the pumps have few moving parts and require no electrical power source, making them ideal for hazardous environments where electrical sparks could pose risks.

Haskel’s engineering philosophy is centered on creating efficient, compact designs that deliver maximum output with minimal energy input. The compact form factor is particularly valuable in industries where space constraints are critical, such as aerospace and offshore platforms. Additionally, a Haskel gas booster pump is often used to enhance operational efficiency in these demanding environments.

Key Features of Haskel Pumps

Haskel pumps boast several features that enhance their performance and reliability:

- Corrosion Resistance: Constructed from materials that withstand corrosive substances, ensuring longevity.

- High Durability: Designed to endure extreme conditions without compromising functionality.

- Fluid Compatibility: Capable of handling a wide range of fluids, including viscous and low-lubricity media.

Additionally, Haskel pumps feature modular designs that allow for easy customisation to meet specific industrial requirements. The flexibility to adapt these pumps to unique applications ensures they remain relevant across diverse operational contexts. In particular, a hydrostatic test pump plays a critical role in pressure integrity testing across multiple industries.

These attributes make Haskel pumps suitable for various applications across multiple industries.

Why Choose Haskel Pumps?

Choosing Haskel pumps comes with numerous benefits:

- Reliability: Their robust design ensures consistent performance in demanding environments.

- Ease of Maintenance: With fewer moving parts, maintenance is simplified, reducing downtime.

- Global Recognition: Haskel has built a reputation as a trusted brand over more than 75 years in the industry.

Energy Efficiency: Pneumatic-driven mechanisms reduce energy consumption, providing cost-effective operation over time.

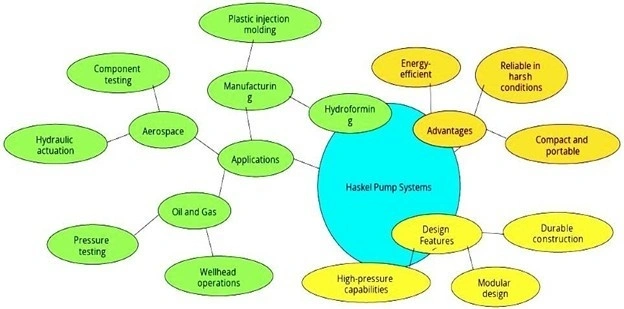

Applications of Haskel Pumps in High-Pressure Environments

Oil and Gas Industry

In the oil and gas sector, Haskel pumps are integral to various processes:

- Gas Compressor System: They provide reliable pressurisation for gas transfer.

- Hydrostatic Testing: Essential for testing the integrity of pipelines and components under pressure.

- Pressurised Fluid Handling: Used extensively for transferring liquids at high pressures.

Haskel pumps also support subsea applications, ensuring robust operation under extreme underwater conditions. Their rugged designs and high pressure system are tested to withstand high salinity and temperature variations, ensuring reliability in some of the most challenging environments. For offshore needs, pompa haskel is a reliable choice for maintaining operational integrity.

Hydrogen Energy Systems

Haskel pumps play a pivotal role in hydrogen energy systems. They are used as boosters in hydrogen production processes, ensuring efficient transfer and storage of hydrogen gas. Given the rising interest in renewable energy sources, their role is becoming increasingly critical.

Haskel is actively involved in supporting hydrogen refueling stations, a key element in the adoption of hydrogen fuel cell vehicles. Their pumps ensure precise pressure control for fast and safe vehicle refueling. The hydrogen booster functionality within Haskel systems enhances refueling efficiency, meeting the demands of this growing sector.

Industrial Manufacturing

In industrial manufacturing, precise fluid control is paramount. Haskel gas booster pump support production processes by providing accurate pressure regulation. This capability enhances overall system efficiency and product quality.

They also facilitate high-pressure deburring and cleaning applications, essential for maintaining quality standards in sectors such as automotive and electronics manufacturing. A reliable high pressure system powered by Haskel ensure smooth operations across various manufacturing setups.

Aerospace and Defense

Haskel pumps are also utilised in aerospace applications. They are essential for high-pressure testing of components and fueling systems, where reliability is non-negotiable. The aerospace industry’s stringent safety standards make Haskel a preferred choice.

Additionally, Haskel pumps support life-support systems and emergency backup systems on aircraft, showcasing their versatility in critical aerospace operations. A high pressure pump used in these settings are critical to ensuring operational safety and efficiency.

Research and Development

Haskel pumps are invaluable in R&D settings. Their precise pressure control and adaptability enable researchers to simulate extreme conditions, test materials, and innovate new technologies. Laboratories across the world rely on Haskel for experiments requiring consistent high-pressure delivery.

How Haskel Pumps Enhance Industrial Operations

Improving System Efficiency

Haskel pumps optimise fluid transfer and pressure regulation. By maintaining consistent pressure levels, they help reduce operational downtime. This efficiency translates into increased productivity across various industrial operations.

In applications involving long operational cycles, such as offshore drilling, the energy efficiency of Haskel pumps significantly reduces overall operational costs, enhancing profitability for businesses. These benefits are amplified when a haskel pump distributor provide localized, timely support for system maintenance.

Enhancing Safety Standards

Safety is paramount in high-pressure environments. Haskel pumps incorporate several safety features:

- Pressure Control Mechanisms: These prevent over-pressurisation.

- Leak-Proof Designs: Ensuring that fluids do not escape during operation.

- Automatic Shutoff: Advanced models include safety mechanisms that shut down operations in the event of anomalies, reducing risks to personnel and equipment.

Such features contribute to safer working conditions and compliance with industry regulations.

Reducing Costs Over Time

The durability and low-maintenance nature of Haskel pumps lead to significant cost savings over time. Their robust design minimizes the need for frequent replacements or repairs, making them a cost-effective solution for high-pressure applications.

Businesses that adopt Haskel technology also benefit from reduced insurance premiums due to enhanced safety features, providing a financial incentive to invest in high-quality equipment. The support of a haskel pump distributor ensures long-term reliability and minimal operational disruption.

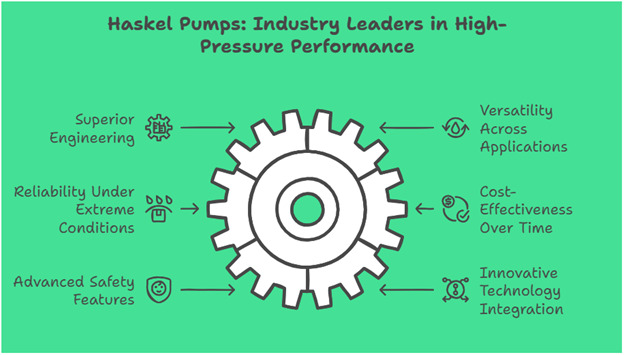

Comparative Analysis: How Haskel Pumps Outperform Competitors in High-Pressure Environments

Haskel pumps have set the industry standard for high-pressure performance by surpassing competitors in several key areas:

Superior Engineering

Haskel pumps are designed with fewer moving parts, minimizing wear and tear and extending service life. Competitor models often incorporate complex mechanisms that require frequent maintenance, leading to increased downtime and operational costs. The Haskel gas booster pump exemplifies this engineering excellence, providing reliability and efficiency across diverse applications.

Versatility Across Applications

While many pumps on the market cater to specific fluids or pressures, Haskel’s advanced engineering ensures compatibility with a wide range of fluids, including corrosive and low-lubricity substances. This versatility allows Haskel pumps to adapt to multiple industries without the need for extensive modifications. Products like the pompa Haskel and hydrostatic test pump are designed to handle such challenges with ease.

Reliability Under Extreme Conditions

In challenging environments such as offshore drilling or aerospace testing, Haskel pumps demonstrate unmatched reliability. Their robust construction and corrosion-resistant materials ensure consistent performance where competitor pumps may fail. The high pressure pump and hydraulically driven gas compressor are particularly noted for their durability in these extreme settings.

Cost-Effectiveness Over Time

Although the initial investment in a Haskel pump may be higher, their low maintenance requirements and long service life result in significant cost savings over time. In contrast, competitors often offer lower upfront costs but incur higher expenses due to frequent repairs and part replacements. This makes Haskel an ideal choice for a high pressure system.

Advanced Safety Features

Haskel gas booster pump integrate advanced safety mechanisms, such as pressure control systems and automatic shutoff features, which are often absent or less effective in competitor models. These safety features reduce risks to personnel and equipment, enhancing operational reliability. This is especially important in applications like a gas compressor system and a hydrogen booster.

Innovative Technology Integration

Competitors are often slower to adopt smart technologies. Haskel’s introduction of IoT-enabled smart pumps allows for real-time performance monitoring and predictive maintenance, providing a cutting-edge advantage in operational efficiency.

By excelling in these critical areas, Haskel pumps remain the preferred choice for industries that demand precision, reliability, and efficiency in high-pressure operations.

Innovations in Haskel Pump Technology

Advancements in Hydraulically Driven Gas Compressors

Haskel continues to innovate with advancements in a hydraulically driven gas compressor system. These innovations enhance operational efficiency by improving energy conversion rates and reducing operational costs.

Integration with High-Pressure Systems

Haskel pumps seamlessly integrate into high-pressure systems alongside valves, transducers, and fittings. This compatibility ensures that systems function optimally without requiring extensive modifications or additional components.

Smart Pump Technology

The future of pumping technology includes IoT-enabled pumps that allow for remote monitoring and predictive maintenance. Such innovations promise to enhance operational efficiency further by providing real-time data on pump performance.

Smart pumps also enable energy usage analytics, helping businesses identify areas for improvement and adopt more sustainable operational practices.

Case Studies: Real-World Applications of Haskel Pumps

Oil and Gas Exploration

In a major offshore oilfield, Haskel pumps were deployed for hydrostatic testing of pipelines. The pumps operated continuously for weeks under extreme pressure conditions, ensuring pipeline integrity and preventing potential environmental disasters. The reliability and efficiency of the pumps reduced project timelines by specific percentages, thus saving millions in operational costs.

Hydrogen Fueling Stations

A hydrogen refueling station in California incorporated Haskel pumps for high-pressure hydrogen storage and transfer. These pumps ensured rapid and safe refueling for hydrogen-powered vehicles, meeting the growing demand for renewable energy solutions. The station’s operator reported an increase in throughput efficiency due to Haskel’s technology.

Aerospace Testing

In an aerospace R&D facility, Haskel pumps were used to test high-pressure components for spacecraft. Their precision and reliability allowed engineers to simulate space-like conditions, ensuring the safety and performance of critical components. The pumps played a key role in advancing the facility’s testing capabilities.

Find out more case studies here.

Environmental Impact of Haskel Pumps

Energy Efficiency

Haskel pumps’ pneumatic-driven design reduces energy consumption compared to traditional hydraulic pumps. This efficiency not only lowers operational costs but also minimizes the carbon footprint of industrial operations, contributing to sustainability goals.

Reduction in Waste

The durability and long service life of Haskel pumps reduce the need for frequent replacements, minimizing industrial waste. Their ability to handle various fluid types also prevents contamination, promoting environmentally responsible practices.

Support for Renewable Energy

Haskel pumps are integral to hydrogen energy systems and other renewable technologies, supporting the global transition to cleaner energy sources. By enabling efficient energy storage and transfer, they play a pivotal role in reducing reliance on fossil fuels.

Maintenance Best Practices for Haskel Pumps

Regular Inspections

Routine visual inspections help identify wear and tear, ensuring timely maintenance. Check for leaks, corrosion, and component alignment to prevent operational issues.

Use Genuine Parts

Always use manufacturer-approved parts for repairs and replacements. Genuine components ensure compatibility and maintain the pump’s performance standards.

Training and Expertise

Operators should receive proper training to handle and maintain Haskel pumps. Skilled personnel can extend the pump’s lifespan and optimize its performance.

Maintenance Schedules

Adhere to recommended maintenance schedules provided by Haskel. Regular servicing helps avoid unplanned downtime and ensures long-term reliability.

Conclusion

Haskel pumps have earned their reputation as reliable solutions for high-pressure environments across various industries. Their advanced technology, coupled with key features like corrosion resistance and ease of maintenance, makes them an ideal choice for engineers and technicians working in demanding conditions.

With applications spanning oil and gas, hydrogen energy systems, industrial manufacturing, aerospace, and research, a haskel gas booster pump continues to set the standard for performance and reliability.

As industries evolve towards more sustainable practices, the role of efficient equipment like Haskel pumps will only grow more critical. Investing in these reliable solutions not only enhances operational efficiency but also contributes to long-term cost savings—a vital consideration for decision-makers across high-pressure industries.

Furthermore, Haskel’s commitment to innovation ensures their technology remains at the forefront of high-pressure solutions, positioning them as a key player in driving industrial progress in the years to come.

Ready to optimise your systems with cutting-edge Haskel Pumps? Contact us today to explore tailored solutions for your industrial needs.

)