Introduction

Hydraulic pumps are essential in many industries, including manufacturing, construction, automotive, and aerospace. They generate the power needed to operate machinery, ensuring efficiency and precision in demanding tasks. Two of the most commonly used types are air-driven and electric hydraulic pumps.

While both convert mechanical energy into hydraulic power, they differ in operation, efficiency, and suitability for various environments. Choosing the right pump is crucial, whether for a hydrostatic test pump, a high-pressure pump, or a gas compressor system.

Air-Driven Hydraulic Pumps: Pros and Cons

How Air-Driven Hydraulic Pumps Work

Air-driven hydraulic pumps, or pneumatic hydraulic pumps, use compressed air to generate hydraulic pressure. They rely on an external air compressor to drive a piston or diaphragm, enabling fluid transfer without electricity.

A key advantage is their safety in hazardous environments, making them ideal for oil and gas, mining, and chemical processing, where fire risks exist. They are widely used in high-pressure gas compressor systems and as hydraulically driven gas compressors.

Pumps like the Haskel pump and Haskel gas booster pump are valued for their simple design, low maintenance, and durability, making them perfect for hydrostatic test pumps and high-pressure pump applications.

Advantages of Air-Driven Hydraulic Pumps

- Lightweight & Portable – More compact than electric pumps, making them easy to transport and ideal for field operations.

- Safe for Hazardous Environments – No electrical components mean no risk of sparks or overheating, perfect for oil and gas, chemical processing, and mining.

- Low Maintenance – Fewer moving parts reduce mechanical failures, downtime, and repair costs.

Disadvantages of Air-Driven Hydraulic Pumps

- Lower Efficiency – Energy losses from heat dissipation and air leakage lead to higher operational costs.

- Air Supply Dependence – Requires a continuous compressed air source; disruptions can halt operations.

- Limited Pressure & Flow – Produces lower pressure and flow rates, making it less suitable for high-demand applications.

Electric Hydraulic Pumps: Pros and Cons

How Electric Hydraulic Pumps Work

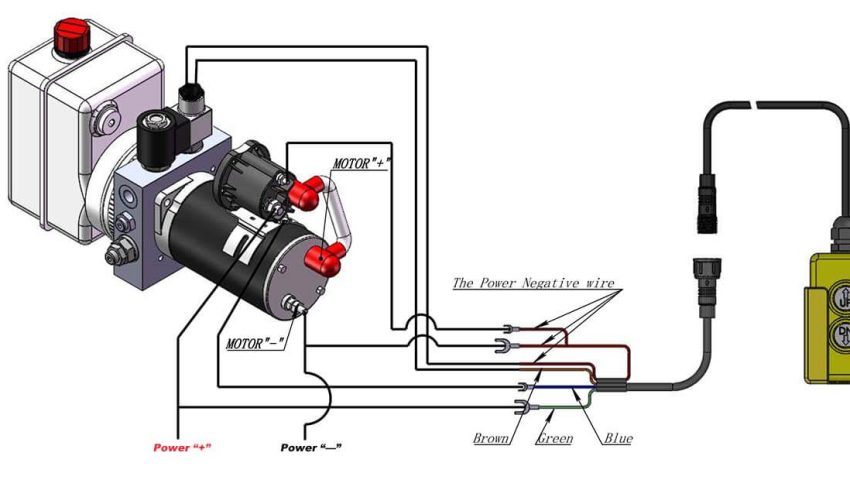

Electric hydraulic pumps use a motor-driven pump to pressurise hydraulic fluid. They require a direct power source, either a standard outlet or an industrial supply.

With gear, vane, or piston mechanisms, they deliver higher pressure and flow rates than air-driven pumps, making them ideal for high-pressure gas compressors and gas compressor systems.

Best suited for environments with a stable power supply, they are widely used in manufacturing, construction, and heavy machinery. They also play a key role in hydrostatic test pumps, Haskel gas booster pumps, and hydraulically driven gas compressors, ensuring reliable high-pressure pump performance.

Advantages of Electric Hydraulic Pumps

- High Efficiency & Performance – Converts electricity to hydraulic power with minimal losses, reducing operating costs.

- Consistent Pressure & Flow – Delivers steady, reliable performance, ideal for precision applications.

- Suitable for High-Pressure Use – Generates higher pressure and flow rates, perfect for heavy-duty industrial applications.

Disadvantages of Electric Hydraulic Pumps

- Heavy & Less Portable – Bulkier due to the motor and electrical components, limiting mobility.

- Higher Costs – Expensive upfront and requires regular maintenance, increasing long-term expenses.

- Not for Hazardous Areas – Risk of sparks or overheating, making them unsafe for flammable environments.

Comparative Analysis: Air-Driven vs. Electric Hydraulic Pumps

Performance Comparison

| Factor | Air-Driven Hydraulic Pumps | Electric Hydraulic Pumps |

| Efficiency | Less efficient due to energy losses from compressed air. | More energy-efficient with direct electrical-to-hydraulic conversion. |

| Pressure Output | Limited pressure, suitable for low to medium-demand applications. | Higher pressure, ideal for heavy-duty applications. |

| Flow Rates | Lower and may fluctuate depending on air supply. | Higher and more consistent for sustained operation. |

| Portability | Lightweight and easy to transport. | Heavier and less portable due to electrical components. |

| Safety | No risk of sparks, making it ideal for hazardous environments. | Potential risk of sparks and overheating; unsuitable for explosive environments. |

| Maintenance | Low maintenance with fewer moving parts. | Requires regular maintenance of motor and electrical components. |

| Application Suitability | Best for hazardous environments, mobile use, and intermittent applications. | Best for high-performance, continuous-use applications in industrial settings. |

Cost Comparison

| Cost Factor | Air-Driven Hydraulic Pumps | Electric Hydraulic Pumps |

| Upfront Costs | Generally lower initial cost. | Higher initial investment due to motor and electrical components. |

| Operating Costs | Higher due to energy inefficiencies in compressed air systems. | Lower, as electricity is a more efficient power source than compressed air. |

| Maintenance Costs | Lower, with fewer moving parts and no electrical components to service. | Higher, requiring motor and electrical system maintenance. |

| Long-Term Cost-Effectiveness | May become expensive over time due to inefficiencies and compressed air system maintenance. | More cost-effective in the long run due to energy efficiency and consistent performance. |

Safety and Environmental Considerations

| Factor | Air-Driven Hydraulic Pumps | Electric Hydraulic Pumps |

| Safety Features | No electrical components, eliminating the risk of sparks or overheating. Safe for hazardous and explosive environments. | Requires electrical power, posing risks of sparks, overheating, and potential electrical failures. Not suitable for flammable or explosive environments. |

| Workplace Safety | Lower risk in volatile environments such as chemical plants, oil refineries, and mining sites. | Requires proper grounding and safety measures to prevent electrical hazards. |

| Environmental Impact | Can be inefficient due to air leaks and the high energy consumption of air compressors, leading to higher carbon footprints. | More energy-efficient, reducing overall power consumption and environmental impact. However, electricity generation may have indirect environmental effects. |

| Noise Levels | Can be noisy due to compressed air operation. | Generally quieter, making them more suitable for noise-sensitive environments. |

Factors to Consider

| Factor | Air-Driven Hydraulic Pumps | Electric Hydraulic Pumps |

| Application Requirements | Suitable for low to medium-pressure applications with moderate flow rates. Best for intermittent use. | Ideal for high-pressure applications requiring consistent flow and continuous operation. |

| Portability | Lightweight and easy to move, making it suitable for mobile and field applications. | Heavier and less portable, best for stationary industrial setups. |

| Operating Environment | Safe for hazardous and explosive environments (no risk of sparks). | Requires a controlled, non-hazardous environment due to electrical components. |

| Budget | Lower initial cost but higher operating expenses due to air compressor inefficiencies. | Higher upfront cost but lower long-term operational expenses due to energy efficiency. |

| Long-Term Costs | Higher costs over time due to energy losses and compressed air maintenance. | More cost-effective in the long run due to lower energy consumption and efficiency. |

Industry-Specific Recommendations

Different industries have distinct requirements when it comes to hydraulic pumps. In construction, electric hydraulic pumps are preferred due to their ability to provide consistent high pressure for heavy machinery such as cranes, lifts, and hydraulic presses. Their efficiency and continuous operation make them ideal for long-duration tasks. Similarly, manufacturing industries benefit from electric pumps, especially in automated systems like injection moulding and metal forming, where a steady flow rate and reliability are crucial.

On the other hand, industries dealing with hazardous environments, such as oil and gas, rely on air-driven hydraulic pumps. Since these pumps do not have electrical components, they eliminate the risk of sparks, making them safer for explosive settings.

Frequently Asked Questions (FAQ)

What is the Main Difference Between Air-Driven and Electric Hydraulic Pumps?

The key difference is their power source. Air-driven hydraulic pumps use compressed air, making them safer for hazardous environments and more portable, but they are less energy-efficient. Electric hydraulic pumps use an electric motor, providing higher efficiency, consistent pressure, and greater power, but they are heavier and not suited for explosive environments.

Air-driven pumps are best for safety and mobility, while electric pumps are ideal for efficiency and continuous operation.

Which Pump Is Better for High-Pressure Applications?

For high-pressure applications, electric hydraulic pumps are the better choice. They provide higher pressure, consistent flow rates, and greater efficiency, making them ideal for heavy-duty tasks in industries like construction, manufacturing, and aerospace. Unlike air-driven pumps, which have limited pressure output and may fluctuate with air supply, electric pumps deliver steady and powerful performance, ensuring reliability in demanding applications.

If your work requires continuous high-pressure operation, an electric hydraulic pump is the best option.

Can Air-Driven Pumps Be Used in Hazardous Environments?

Yes, air-driven hydraulic pumps are ideal for hazardous environments. Since they operate using compressed air instead of electricity, they eliminate the risk of sparks, overheating, or electrical failures, making them safe for explosive or flammable settings such as oil refineries, chemical plants, and mining sites.

Their lightweight and portable design also makes them easy to use in remote or confined spaces where electrical equipment may be restricted. For industries prioritising safety in volatile conditions, air-driven pumps are the preferred choice.

Conclusion

Both air-driven and electric hydraulic pumps have their strengths and limitations. Air-driven pumps are lightweight, portable, and safe for hazardous environments, but they are less efficient and dependent on a continuous air supply. On the other hand, electric hydraulic pumps offer higher efficiency, consistent pressure, and better performance for high-pressure applications, but they are heavier, require electricity, and may not be suitable for explosive environments.

Choosing the right pump depends on your specific application and operating environment. If safety and mobility are top priorities, an air-driven pump is the best option. If efficiency and power are more important, an electric hydraulic pump is the way to go.

To ensure you select the best pump for your needs, consider consulting with experts or suppliers who can provide personalised recommendations based on your industry and requirements.

)