Pressure gauge calibration in high-pressure systems is essential for ensuring accuracy, compliance, and system safety. At Hydratech, we specialize in high-pressure system integration and offer professional pressure gauge calibration services accredited by SAC-Singlas. Proper calibration ensures reliability, compliance with industry standards, and significant cost savings for our customers.

Contents

- Why is Pressure Gauge Calibration Necessary?

- The Importance of Calibration in High-Pressure Systems

- How Pressure Gauge Calibration Saves Customers Money

- Hydratech SAC-Singlas Accredited Calibration Services

- Conclusion

Why is Pressure Gauge Calibration Necessary?

Pressure gauges are essential instruments in many industries, including oil and gas, manufacturing, and chemical processing. Over time, environmental conditions, mechanical wear, and exposure to extreme pressures can lead to inaccuracies. Regular calibration corrects these deviations, ensuring that the readings remain accurate and reliable. Without proper calibration, businesses risk operational inefficiencies, compromised safety, and regulatory non-compliance.

The Importance of Calibration in High-Pressure Systems

High-pressure systems operate at extreme conditions where even minor inaccuracies can lead to serious consequences, including equipment failure, production downtime, and safety hazards. Accurate pressure measurement is crucial for:

- Ensuring Process Safety: Prevents overpressure conditions that may result in system failures or accidents.

- Regulatory Compliance: Many industries require regular calibration to meet safety and quality standards.

- Prolonging Equipment Lifespan: Proper calibration minimizes wear and tear caused by incorrect pressure settings.

- Optimizing Performance: Ensures that systems operate efficiently, reducing unnecessary energy consumption.

How Pressure Gauge Calibration Saves Customers Money

Regular calibration of pressure gauges can lead to significant cost savings by:

- Reducing Downtime: Faulty pressure gauges can cause system failures, leading to unplanned shutdowns and costly repairs.

- Preventing Overuse of Resources: Incorrect pressure readings can result in excessive use of materials, increasing production costs.

- Avoiding Regulatory Fines: Non-compliance with industry standards can lead to penalties and legal liabilities.

- Extending Equipment Life: Preventing pressure-related stress on components reduces maintenance and replacement costs.

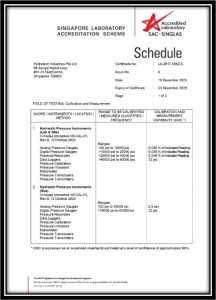

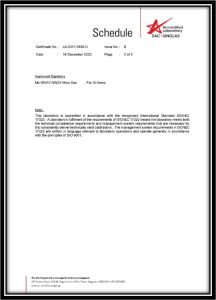

Hydratech SAC-Singlas Accredited Calibration Services

At Hydratech, we offer SAC-Singlas accredited pressure gauge calibration services to ensure the highest level of accuracy and compliance. Our calibration services include:

- State-of-the-art Calibration Equipment: We use precision instruments to achieve highly accurate results.

- Experienced Technicians: Our experts are trained to handle various types of pressure gauges.

- Comprehensive Reports: We provide detailed calibration certificates that meet industry standards.

- Fast Turnaround Time: We minimize downtime by offering efficient calibration services.

Conclusion

Regular pressure gauge calibration is essential for maintaining safety, efficiency, and cost-effectiveness in high-pressure systems. Hydratech SAC-Singlas accredited services ensure that businesses receive reliable and compliant calibration solutions. Contact us today to learn more about how we can help keep your high-pressure systems operating at peak performance.

For more information, visit our calibration services page: Hydratech Calibration Services

)